Purchase instructions:

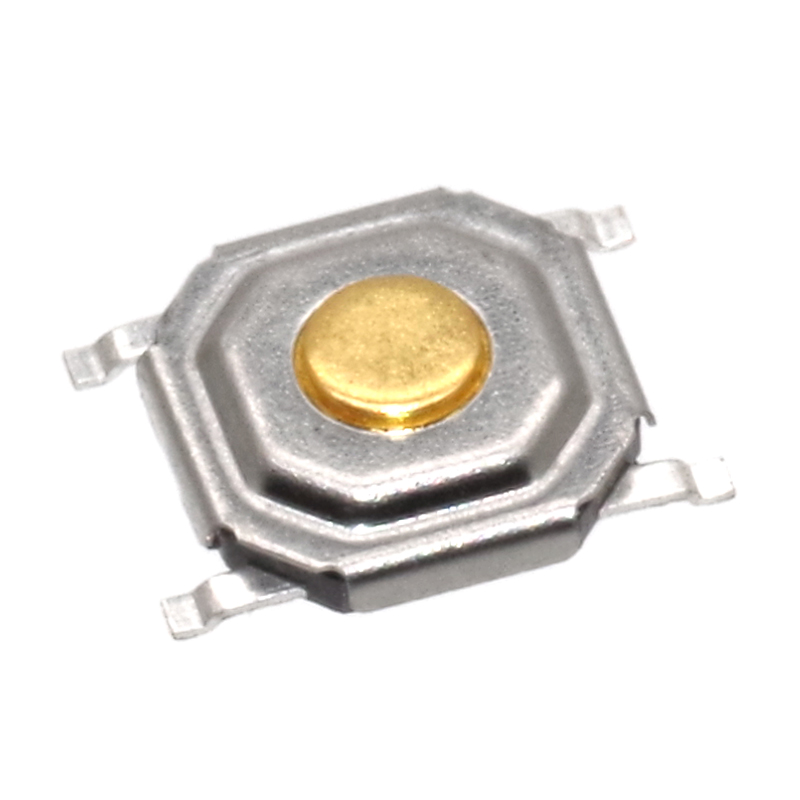

The quality of the switch will directly affect the use of the product, so we must understand it clearly before buying. Before purchase, pay attention to its weldability, protection, conductivity and other electrical properties, and whether the service life and the positive and negative tolerance of hand feel are within a reasonable range. External factors are also very important. Although we are not the appearance Association, the appearance of products can affect the quality of products. In order to reduce the resistance, we will use silver plating on the pins. High quality products will use the process of silver plating on the pins. The process is also controlled. The thickness of silver plating should be more than 0.3um in order to effectively prevent pin oxidation.

Precautions for use:

A good product should also be used well in order to give full play to the efficacy of the product. The production conditions shall be confirmed before use, and different welding methods shall select impassable pins and impassable temperature resistant materials. Due to different conditions, the methods of pins are also different. Pins are divided into plug-in type and patch type. After production, the performance of the switch must be tested, whether the switch is normally on and off, whether the hand feeling changes, whether the product resistance is normal, whether the product appearance is normal, whether the switch pin is in the welding position, etc. reasonable production SOP shall be formulated for unused production processes.

Influence of metal shrapnel on switch:

The switch is evolved from the pot chip, which is the earliest membrane switch used. Its structure is single and its production speed is fast. However, the product has low service life and single performance, which can not meet the market demand. According to the increasing demand for product performance, simple pot pieces have been gradually eliminated by the market. What follows is that we touch the switch, and its operation principle is the same. It is the upgraded version of Guozi film, and its heart is Guozi film. Looks like iron man.

At the initial stage of use, consumers only have requirements for the quality and performance of products. With the improvement of market products and consumption level, the quality and performance of products can not meet consumers. Those who are familiar with the switch know that the switch has its feel. In short, it is the strength of the switch. Touch, press, toggle and micro motion these switches have strength parameters. Industry standard: micro motion strength 30-100gf, key strength 250-400gf, toggle strength 200-400gf, touch 50-400gf. The quality of hand feel is directly related to the strength. The smaller the positive and negative tolerance range of force, the better the hand feeling. The positive and negative tolerance range of shrapnel produced in China is larger, and the value is plus or minus 50; The range of positive and negative tolerance of shrapnel produced in Korea is relatively medium, with a value of plus or minus 30; The shrapnel imported from Japan is also the best shrapnel in the world. The positive and negative tolerance range of Japanese ternary shrapnel used by Shuo Fang is very small, with a value of plus or minus 10. Conclusion: the higher the precision of the shrapnel, the better the touch of the switch.

The working principle of the switch: the switch can be turned on by pressing the switch button during operation. When the button is released, the switch is turned off, and its internal structure is realized by the force of metal shrapnel. There are two kinds of working principle of shrapnel: metal shrapnel. Shrapnel is made of phosphor copper and stainless steel. There are two kinds of electroplating processes: silver plating and gold plating. Shuofeng's gold plating and silver plating processes are more than 0.3um. The electroplating process directly affects the electrical performance and oxidation resistance of the product.